Digital Printing vs. Screen Printing

Digital printing is a mostly automated process that uses print heads to apply a design to a product. Instead of mesh screens, digital printing relies on computer design files.

In digital printing, all the colors specified in the design are mixed from four base colors – cyan, magenta, yellow, black. Just like your inkjet printer, the print heads lay down incredibly tiny dots of each of the four base colors that then blend together to achieve the final look.

After the printer applies inks to the glass surface, the inks are cured with UV light and bonded to the product.

Screen printing boils down to pushing ink through a mesh screen onto the item being printed, such as fabric or glass.

- The glass to be printed on is secured in place on a form or jig.

- A stencil (the screen) with the design, one for each color, is laid over the glass.

- Ink is pressed through the stencil onto the glass.

The printed design is then cured with heat or UV light that bonds it permanently to the surface.

Digital Printing

Edges

Screen printing has the ability to produce slightly sharper edges and more crisp lines.

Screen Printing

Digital Print vs. Screen Print

Screen printing’s strength is large area of a single color; digital is better suited for high color counts and designs featuring gradients. Here are some things to consider when choosing a print method.

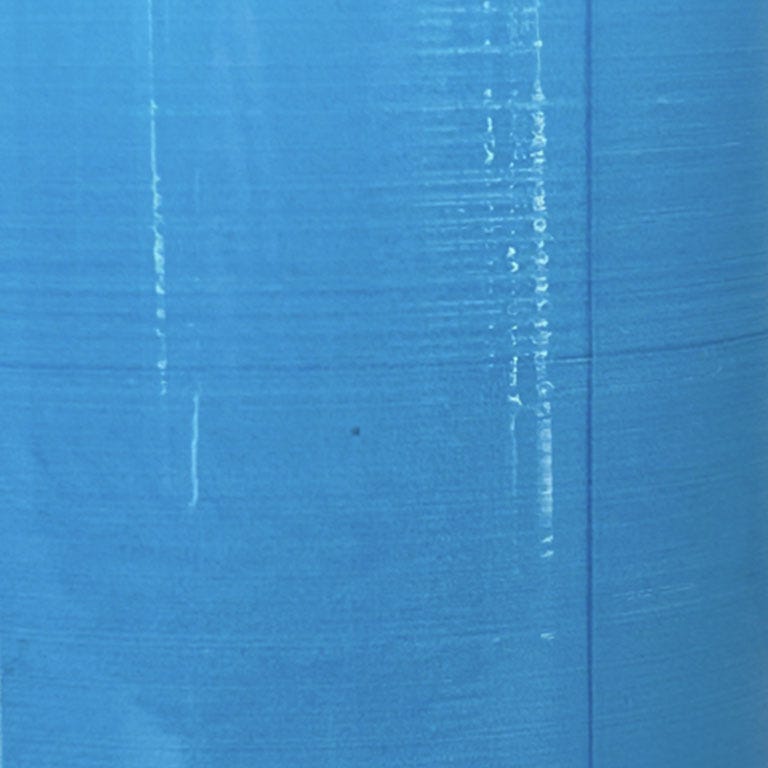

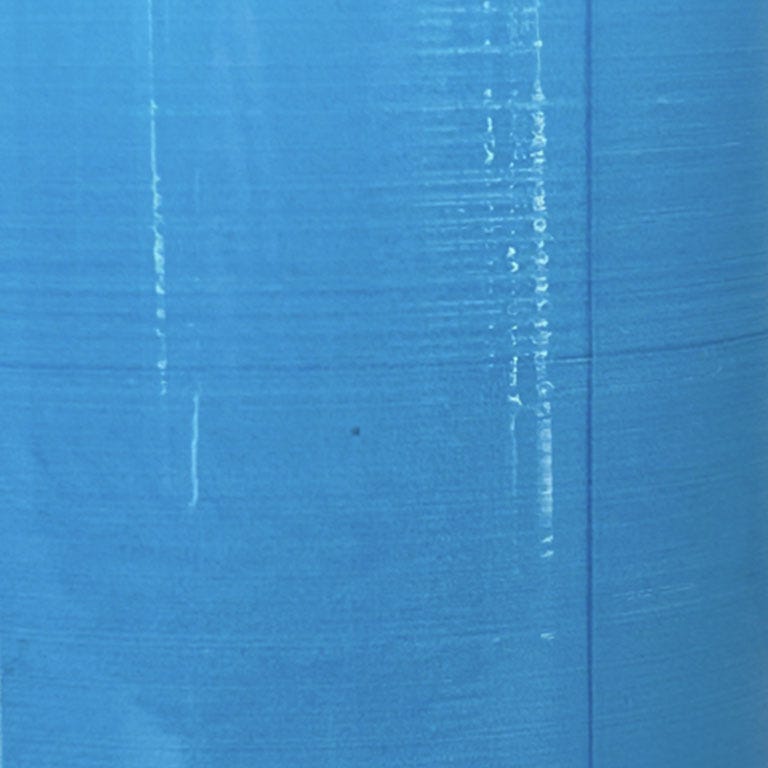

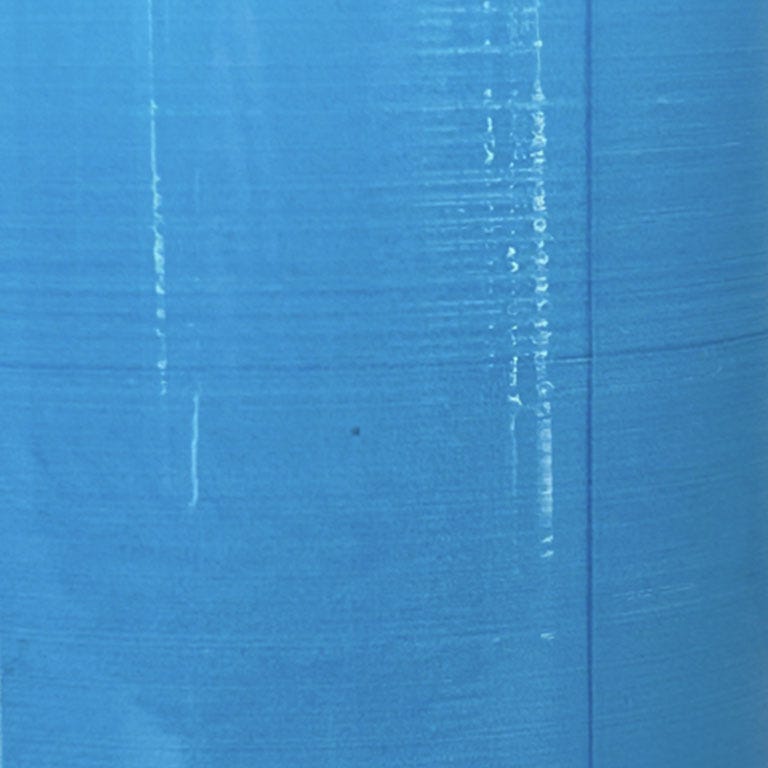

Digital Printing

Flat Colors

Banding lines may occur in digital printing when the designs feature a large area of a single color.

Screen Printing

Digital Printing

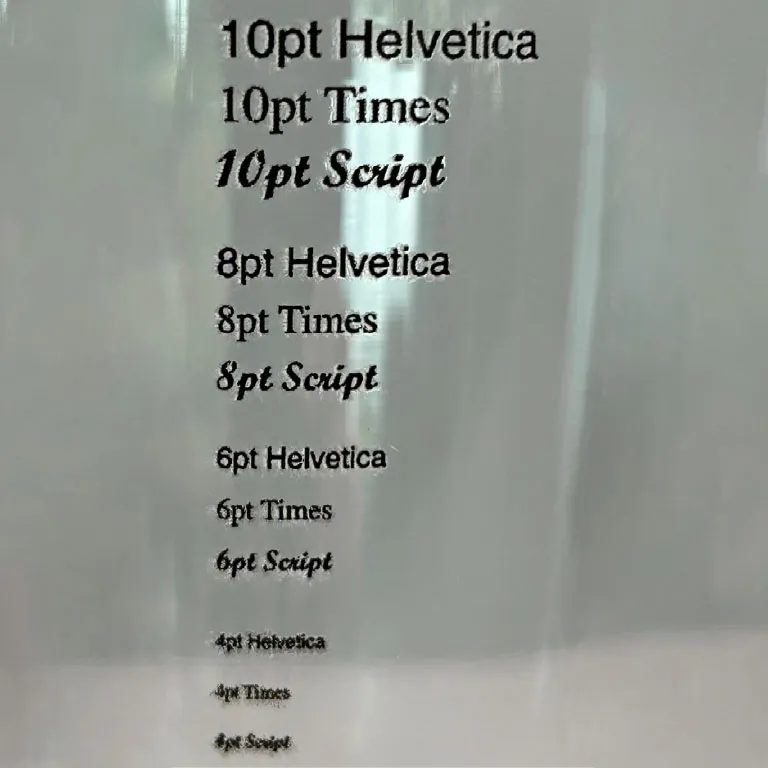

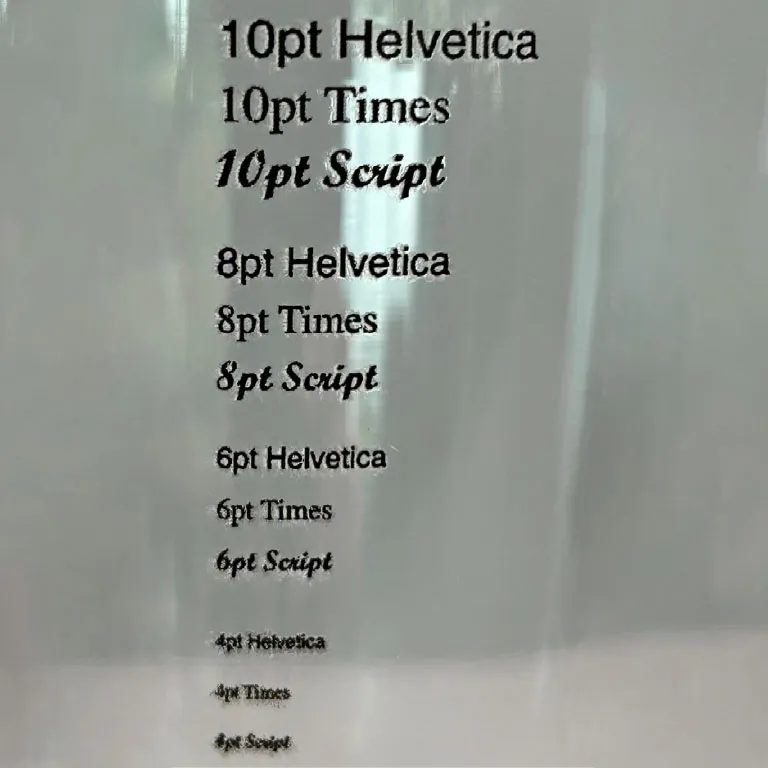

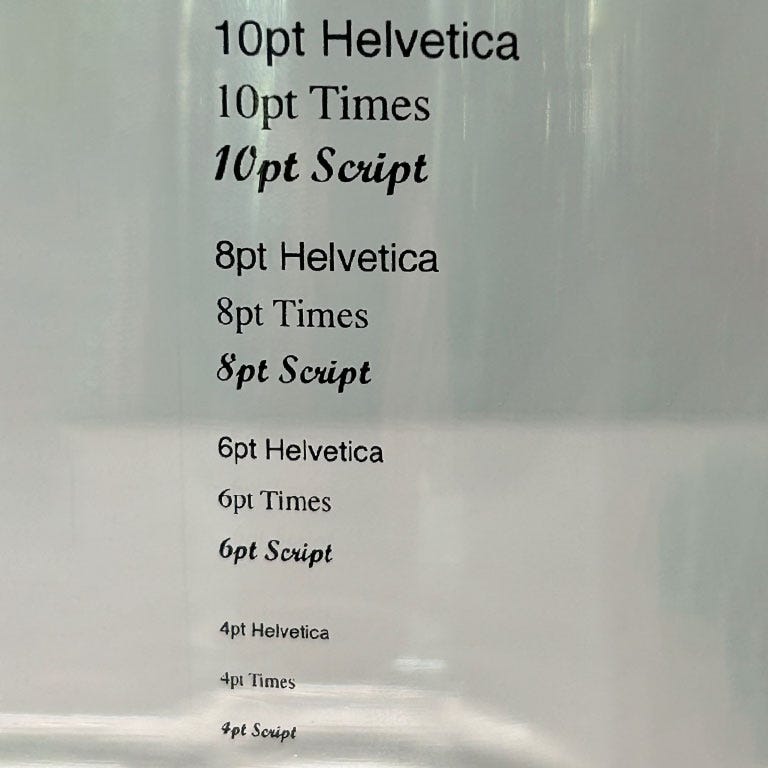

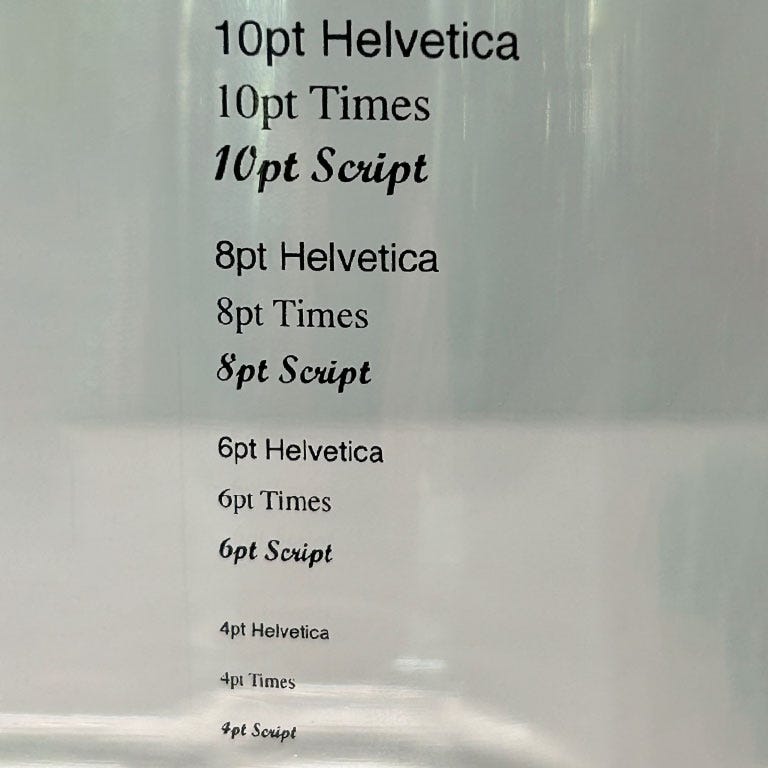

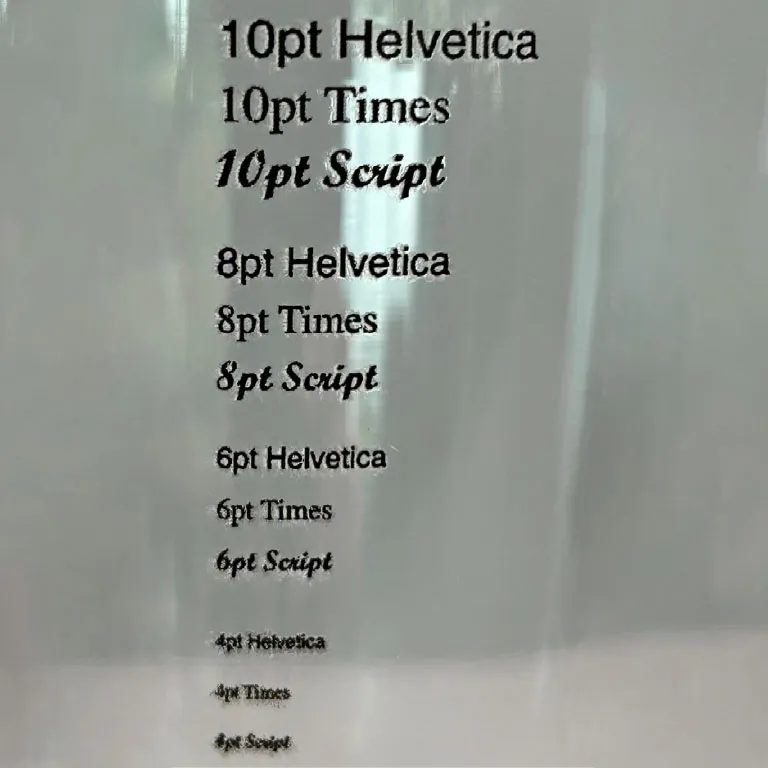

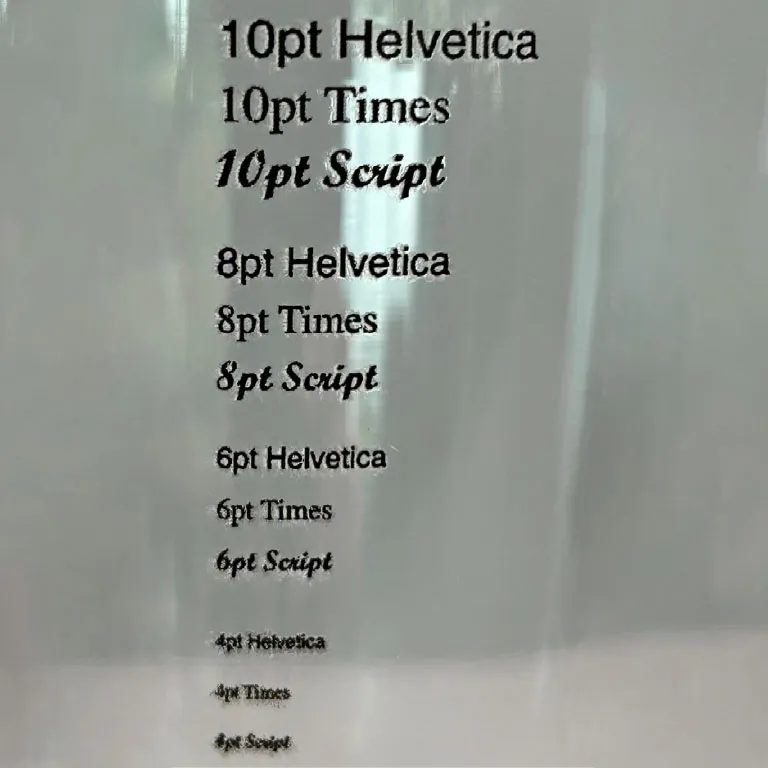

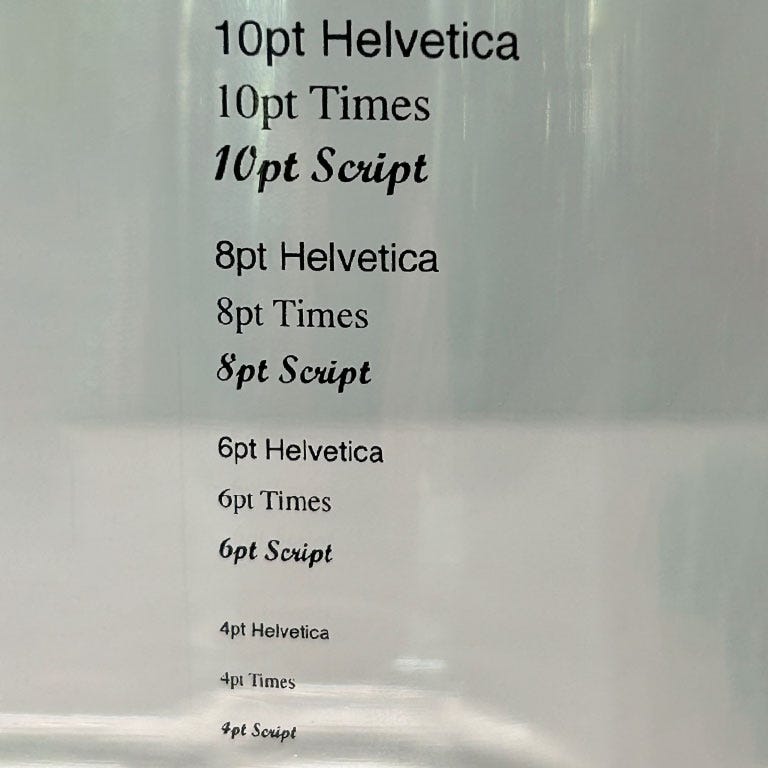

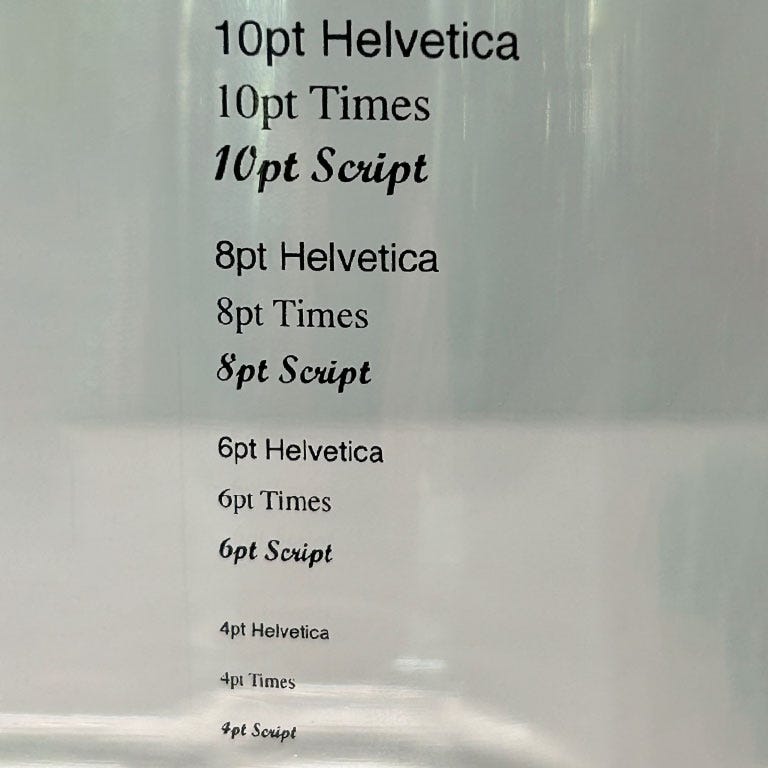

Small Text

Small text is more legible in screen print.

Screen Printing

Digital Printing

Gradients/Halftones

Digital printing is the best choice for designs that have many colors and gradients (or halftones).

Screen Printing

Digital Printing

Print Area

Digital printing can allow for a larger print area than screen printing on select glassware.

Screen Printing

Digital Printing

Contrast

Greater color contrast is achievable with screen print.

Screen Printing

What Process Should You Choose?

Digital Printing is best for:

- Nuanced details. Designs featuring lots of colors or needing near photo realism. Digital printing can achieve better gradients and halftones of colors.

- Specialty items. Promotions, giveaways, and special releases where glassware will be cleaned via a residential dishwasher and experience noncommercial use.

- Small product runs. Since there are no screens or other involved setup work, smaller runs can be more cost-effective in digital printing. Lead times may also be shorter.

- Full-wrap printing. Digital printing allows for a larger print area and digital print heads can get closer to the edges of the glassware for a “full bleed” look.

Screen Printing is best for:

- Large blocks of color. If your design requires large areas filled with single colors, this is your method.

- Items that require durability. Glassware that will be cleaned in a commercial dishwasher or heavily used (such as at a bar or restaurant) are better suited for screen printing.

- Large product runs. If you plan to print higher quantities, screen printing may be a more economical choice.

- Complex shapes. Grandstand’s use of a blended automatic and semi-automatic production line means screen printing can decorate a wider range of glassware shapes.

Other Considerations

Digital Print Quality

When viewed very closely, certain images or colors may appear pixelated since the digital printing process uses individual dots of base colors to achieve the final result. At typical viewing distances this hardly noticeable.

Digital Print Edge Blur

To increase the durability of your print a protective clear coat is applied to digital prints to prolong your print life. When viewed very closely, smaller elements may see some edge blur. At typical viewing distances this is hardly noticeable.

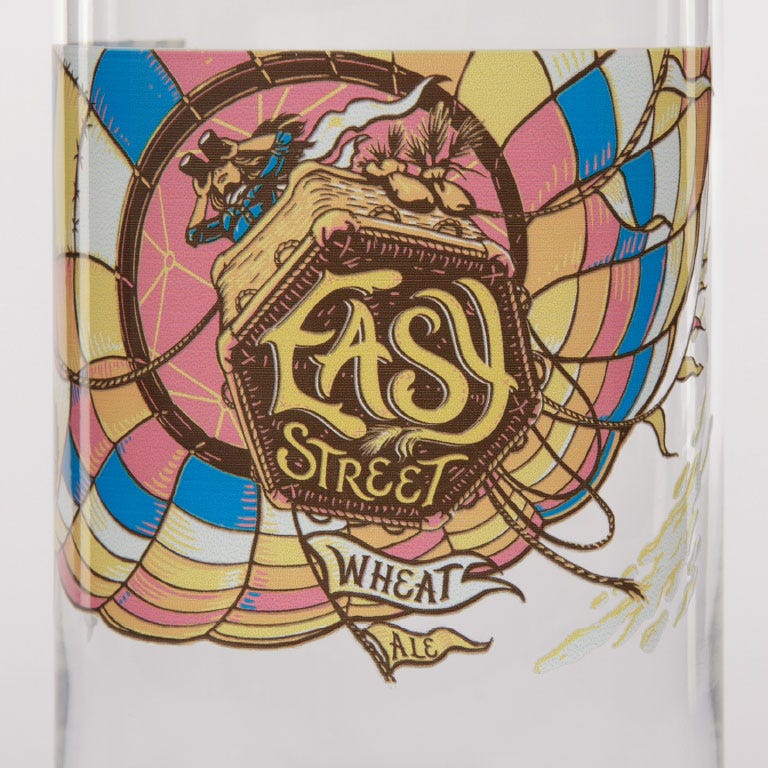

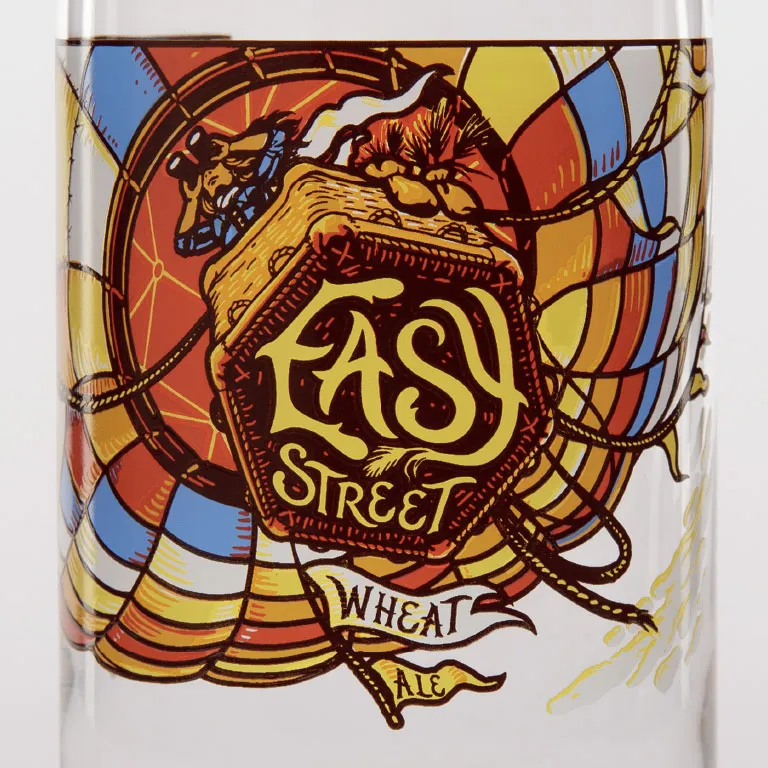

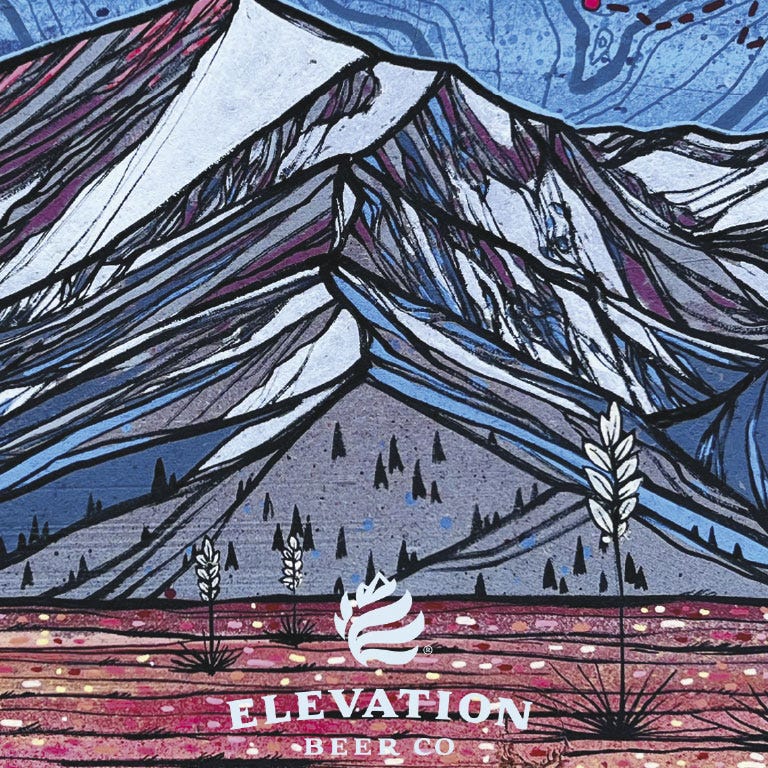

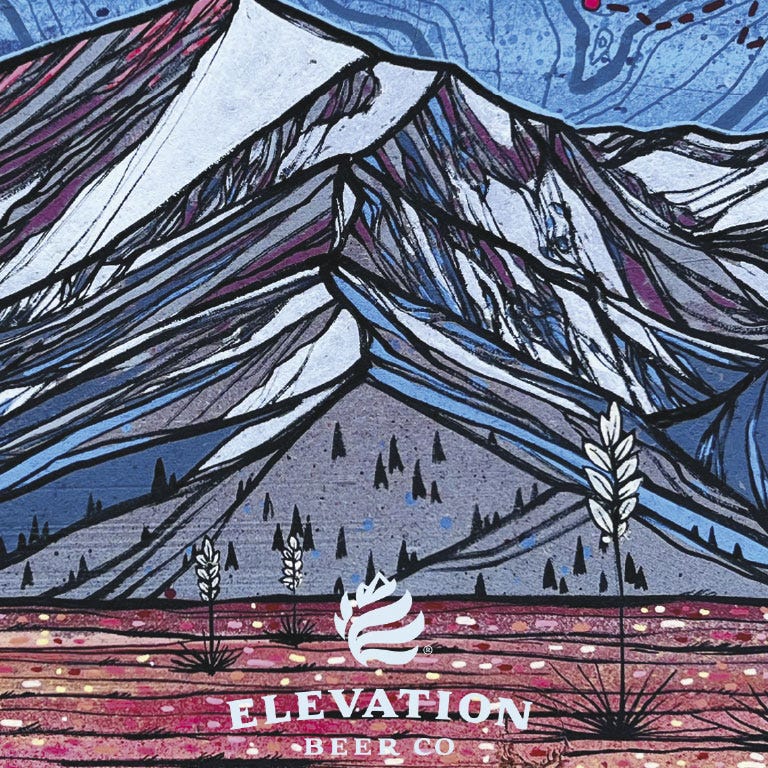

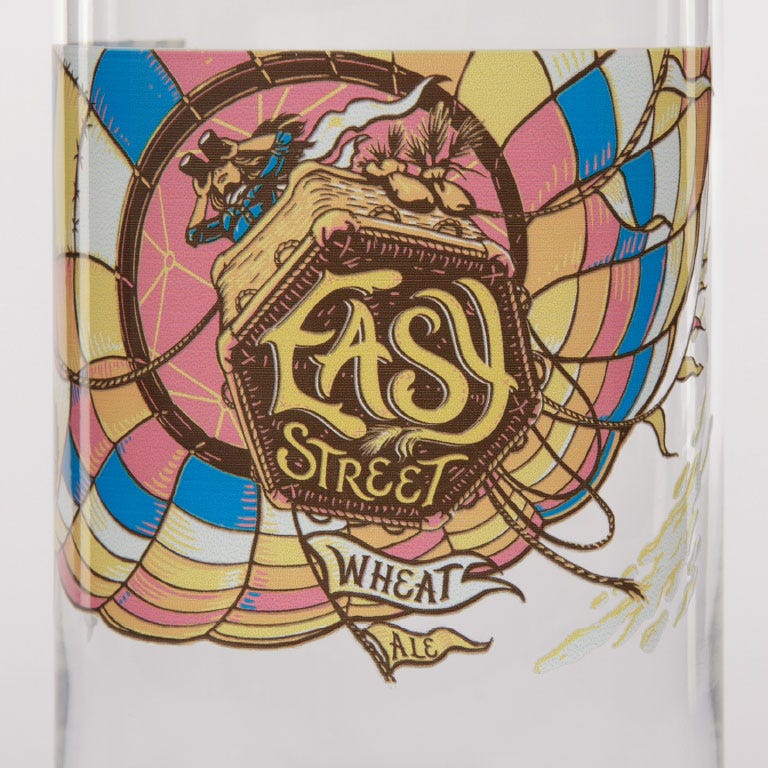

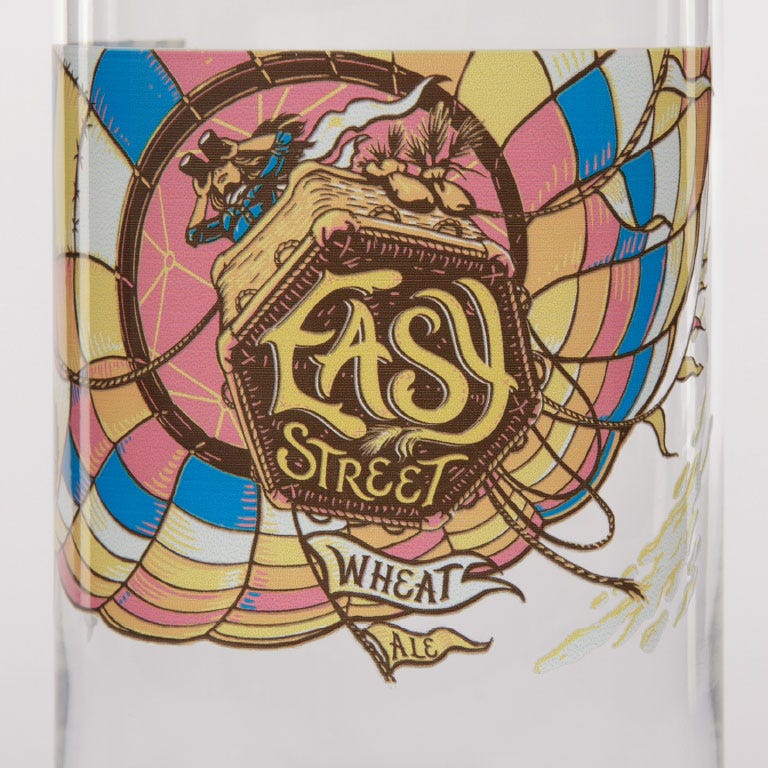

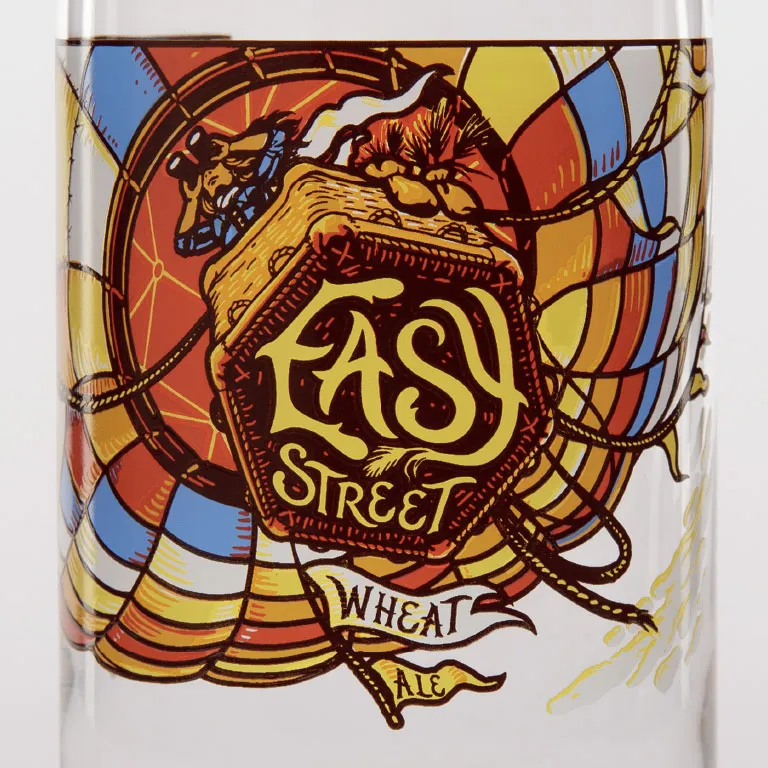

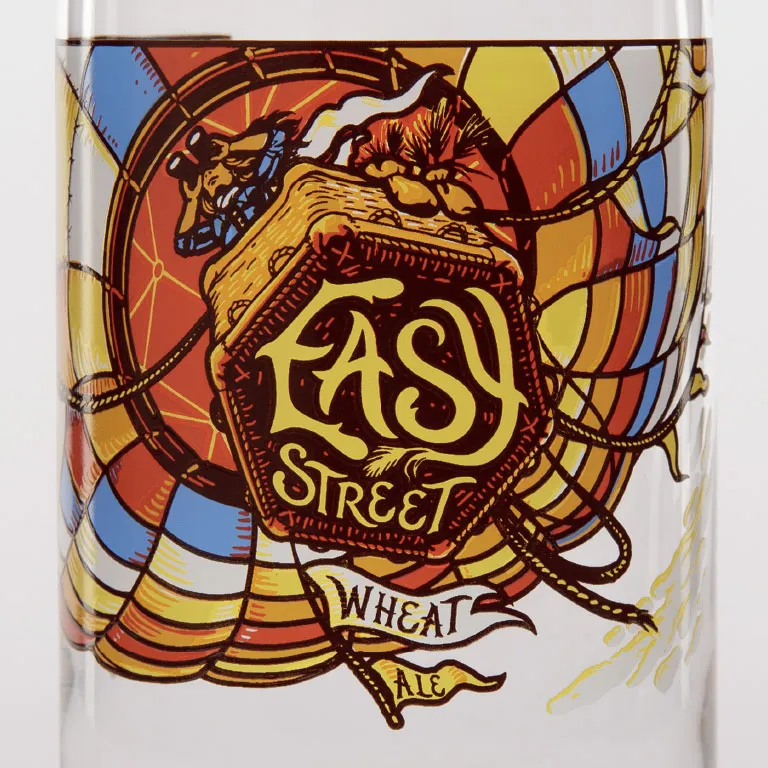

Original Art

Digital Print Details on Tapered Ware

On tapered glassware, the image can become compressed with the glass shape. It is recommended to adjust your artwork to work with the glass shape to avoid losing detail.

Printed Art

Digital Printing vs. Screenprinting

Digital printing is a mostly automated process that uses print heads to apply a design to a product. Instead of mesh screens, digital printing relies on computer design files.

In digital printing, all the colors specified in the design are mixed from four base colors – cyan, magenta, yellow, black. Just like your inkjet printer, the print heads lay down incredibly tiny dots of each of the four base colors that then blend together to achieve the final look.

After the printer applies inks to the glass surface, the inks are cured with UV light and bonded to the product.

Screenprinting boils down to pushing ink through a mesh screen onto the item being printed, such as fabric or glass.

- The glass to be printed on is secured in place on a form or jig.

- A stencil (the screen) with the design, one for each color, is laid over the glass.

- Ink is pressed through the stencil onto the glass.

The printed design is then cured with heat or UV light that bonds it to the surface.

Digital Print vs. Screenprint

Screen printing’s strength is large area of a single color; digital is better suited for high color counts and designs featuring gradients. Here are some things to consider when choosing a print method.

Digital Printing

Flat Colors

Banding lines may occur in digital printing when the designs feature a large area of a single color.

Screen Printing

Digital Printing

Small Text

Small text is more legible in screen print.

Screen Printing

Digital Printing

Gradients/Halftones

Digital printing is the best choice for designs that have many colors and gradients (or halftones).

Screen Printing

Digital Printing

Print Area

Digital printing can allow for a larger print area than screen printing on select glassware.

Screen Printing

Digital Printing

Contrast

Greater color contrast is achievable with screen print.

Screen Printing

What Process Should You Choose?

Digital Printing is best for:

- Nuanced details. Designs featuring lots of colors or needing near photo realism. Digital printing can achieve better gradients and halftones of colors.

- Specialty items. Promotions, giveaways, and special releases where glassware will be cleaned via a residential dishwasher and experience noncommercial use.

- Small product runs. Since there are no screens or other involved setup work, smaller runs can be more cost-effective in digital printing. Lead times may also be shorter.

- Full-wrap printing. Digital printing allows for a larger print area and digital print heads can get closer to the edges of the glassware for a “full bleed” look.

Screen Printing is best for:

- Large blocks of color. If your design requires large areas filled with single colors, this is your method.

- Items that require durability. Glassware that will be cleaned in a commercial dishwasher or heavily used (such as at a bar or restaurant) are better suited for screen printing.

- Large product runs. If you plan to print higher quantities, screen printing may be a more economical choice.

- Complex shapes. Grandstand’s use of a blended automatic and semi-automatic production line means screen printing can decorate a wider range of glassware shapes.

Other Considerations

Digital Print Quality

When viewed very closely, certain images or colors may appear pixelated since the digital printing process uses individual dots of base colors to achieve the final result. At typical viewing distances this hardly noticeable.

Digital Print Edge Blur

To increase the durability of your print a protective clear coat is applied to digital prints to prolong your print life. When viewed very closely, smaller elements may see some edge blur. At typical viewing distances this is hardly noticeable.